Xtender

Battery Regenerator

The all-in-one, fully automated machine for safely discharging, desulfating, and restoring lead-acid (flooded, AGM, or gel traction) batteries' lost capacity. It's a charger and discharger that works even when you're not, shortening the restoration process by days. The built-in Integrated Monitor battery diagnostic software provides even greater insights when paired with our Battery Monitoring System (BMS), individual battery or cell health is wirelessly recorded. Copies of the report may be printed as a PDF, Word, or Excel document.

Battery Regeneration Process

The Xtender is an all-in-one load bank, desulfator, and charger. It works with all lead-acid battery types (VLA (flooded), VRLA (vented), AGM, and GEL). The automatic regeneration process consists of 6 phases.

Phase 1: First controlled discharge

Phase 2: Bulk & absorption charge

Phase 3: Cycle mode

Phase 4: Equalization charge

Phase 5: Second controlled discharge

Phase 6: Bulk & absorption charge

Shark Pulse Technology

A patented high frequency shark pulse technology is applied, negative during discharge and positive during charging. The pulse in combination with a controlled discharge and recharge cycle effectively breaks down the damaging hard sulfate crystals and rejuvenates the battery.

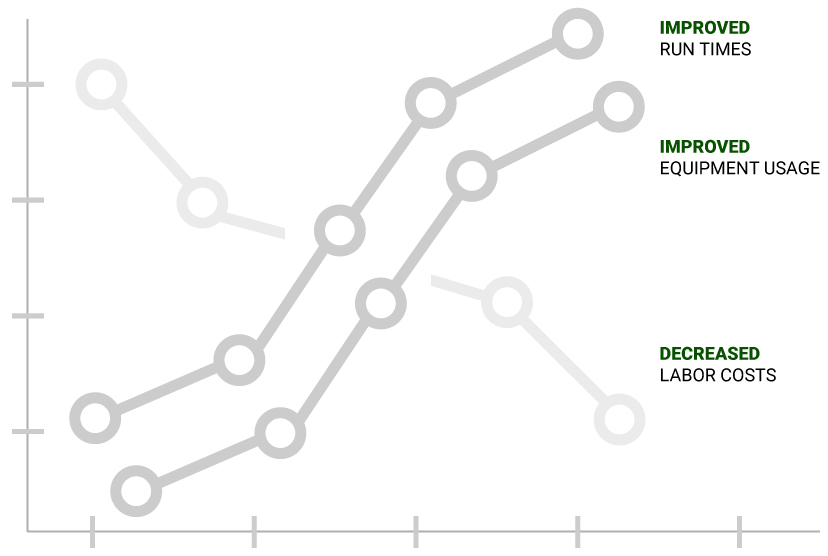

Regenerated batteries require less frequent charging, experience improved run times, and improve equipment usage while reducing labor costs. Batteries may experience up to 50% longer functional life spans.

3 Machines-In-One

3 Models Available

Xtender Battery Regenerators are a load bank, desulfator, and charger to maintain a variety of lead-acid batteries, from golf cars and pallet jacks to high-volume industrial lift trucks and telecommunication systems. All Xtender units may be partnered with our Battery Monitoring System and Smart Discharger or used independently.

Xtender M1001

Analyze, desulfate, restore and maintain batteries commonly used in golf cars, sweeper-scrubbers, walkies, mobility scooters, aerial lifts, and more. Learn More ❯

| Model | Input Voltage | Max Input Current | DC Output Voltage | DC Output Current | Max Amp Hour Rating | Dim. | Wt. | Cert. |

|---|---|---|---|---|---|---|---|---|

| Xtender M1001 | 208–240 V, Single-Phase | 35 A | 1.2 V–100 V | 0–30 A | 300 Ah | 24" x 16" x 52.5" | 273 lbs. | MET |

Xtender M1007

Analyze, desulfate, restore and maintain industrial batteries which are commonly used in pallet jacks, scissor lifts, sweeper-scrubbers, forklifts, and more. Learn More ❯

| Model | Input Voltage | Max Input Current | DC Output Voltage | DC Output Current | Max Amp Hour Rating | Dim. | Wt. | Cert. |

|---|---|---|---|---|---|---|---|---|

| Xtender M1007 | 208-240 V, Three-Phase | 75 A | 1.2 V–125 V | 0–100 A | 1,000 Ah | 24" x 20" x 52.5" | 554 lbs. | MET |

| Xtender M1007-480 | 480 V, Three-Phase | 40 A | 1.2 V–125 V | 0–100 A | 1,000 Ah | 24" x 20" x 52.5" | 554 lbs. | MET |

Increase Your Revenue + Time Saving + Money Savings =

Xtender Battery Regenerator

The Xtender Battery Regenerator provides new possibilities for your business.

Revenue Generator

- Expand service offerings

- Battery Restoration

- Annual battery maintenance programs

- Increased margins vs. selling replacement battery

- Broader customer assortment, cost efficient solutions

Save Time

- Fully automatic; remote monitoring

- One machine does it all; No switching equipment

- Requires less attention

- Works even when you're not

Save Money

- Extend the lifespan for your current fleet

- Minimize the number of new in-stock batteries

Interested?

Want to Experience the Benefits Firsthand?

FSIP offers live demonstrations at your facility with complementary training (on-site or web conference). Training takes ~3-4 hours over 3–4 days. We'll walk your team step by step through battery regeneration including unit operation, programming, reporting, wireless Battery Monitoring System (BMS) operation, and accessory usage. At the end of the training, you will be ready to perform additional battery regenerations on various batteries throughout your facility. Your demonstration unit will remain on-site for your use for seven business days.

The Xtender starts paying for itself with its first use - prolonging battery life, saving replacement battery costs, improving inventory management, and maintaining overall uptime.

Want more information first, contact an Xtender Expert here.